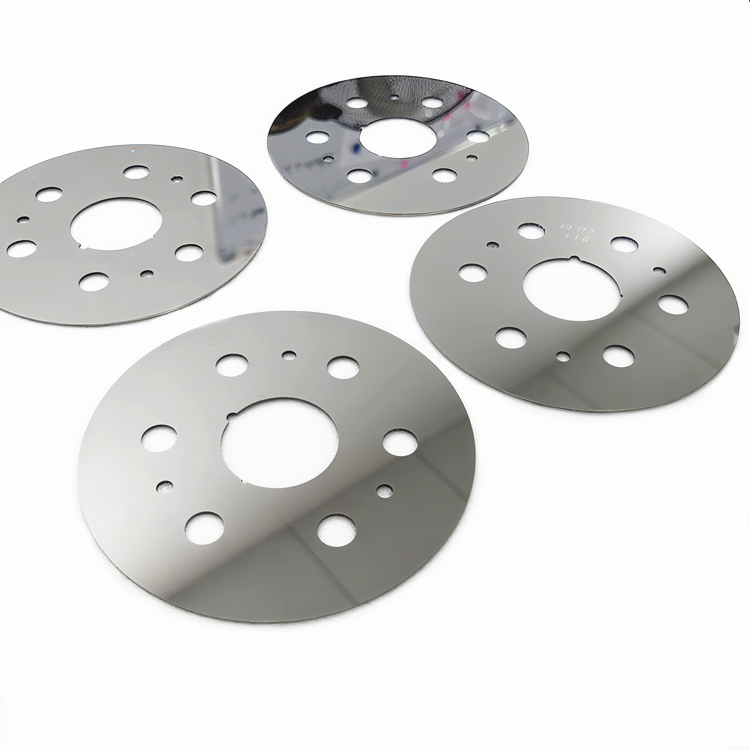

Tungsten carbide Fin Forming Roller Disc Blanks with Long Lifetime

Carbide fin forming roller disc blanks

For more information, warmly welcomr to contact us

Shirley Pan

Email:shirley@chinahardalloy.com

Mobile:+8617773379950

Fin Machine Use Carbide Circular Blade With High Cutting Performance

With over 10 years experience in tungsten carbide manufascturing, our circular carbide blade for hobbing cutter have ecellent cutting performance. It is widely used in fin Machine. We got good feedback from our clients with fast cutting performance, good cutting precision,and long lifetime. It will bring great benefit for you.

Detail Information

1. Material: 100%virgin WC+CO

2. Specification: OD125*ID40*0.79mm (various size)

3. Property: high abrasive resistance, good bending strength, good precision and flatness

4. Surface: high grinding

5. Features: excellent cutting performance and long lifetime,

6. Application: Hobbing cutter of Fin Machine

7. 100% inspection before shipment

8. Fast delivery time: 2 days for inventory, 15-18 dyas for mass manufacturing

9. blank or finished also can be provided

Various dimension for reference(We can manufacture based on your drawing)

Type | Outside Diemater (mm) | Inside Diameter (mm) | Thickness (mm) |

100*ID*T | 100 | 20-40 | 0.55~5 |

125*ID*T | 125 | 20-40 | 0.55~5 |

135*ID*T | 135 | 20-40 | 0.55~5 |

145*ID*T | 145 | 20-40 | 0.55~5 |

170*ID*T | 170 | 20-40 | 0.55~5 |

175*ID*T | 175 | 20-40 | 0.55~5 |

180*ID*T | 180 | 20-40 | 0.55~5 |

Some Recommended Grade for Reference

Grade | ISO | Cobalt % | Density(g/cm3) | Hardness(HRA) |

YG8 | K30 | 8 | 14.8 | 89.5 |

YG6 | K20 | 6 | 14.95 | 90.5 |

YG6X | K10 | 6 | 14.95 | 91.5 |

YL10.2 | K25-K35 | 10 | 14.5 | 91.8 |

YS2T | K30 | 10 | 14.5 | 92 |

More dimension and grades please kindly contact us. We have various grade and size to meet you.

Fully automatic fin molding machine can produce various specifications of aluminum fin, copper fin, stainless steel fin radiating strip products through changing the integral quick change type fin molding tools.

According to the fin materials to be machined by the molding tool it can be divided into:

Aluminum fin molding tool

Copper fin molding tool

Stainless steel fin molding tool

Fin Die British Standard

Fin forming rolling cutter are machined by all top precise imported machines, assembly adjusted by three-coordinates measuring machine, inspected by Fin Measuring System. The precision of forming rollers is very strictly controlled by advanced machines

Production Process:

Powder preparing-Pressing-Sintering-Processing- Finishing

ADD:6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou,Hunan, China 412000

Email:sales@chinahardalloy.com TEL:0731-28215800